Chongqing, China (Mainland)

Deyuan

Foam Filled Polyurethane Fender

Foam Filled Polyurethane Fender

black

Nude packaging,inflated it and piled it up.

About 15 to 30 days

Foam Filled Polyurethane Fender :

Marine Foam Filled Polyurethane Fender :

Foam Filled Polyurethane Fender is a compressive fender, uses polyurethane material as the outer protective layer, and PU foam material or plastic foam as buffer medium, and absorbs impact energy of ships by compressive strain during use, reducing destructive effect on docks and ships. It is mostly characterized by floating performance, and is not affected by tidal range; it has bright color and can be made into products with various colors according to customer demands.with counterforce from small to big, and high energy absorption, it is suitable for open sea open docks and gravity (dolphin) wharfs, especially docks with large tidal range and loading and lightering of two steamers in open sea.

Compared to other marine fenders system:

1. High wear resistance which is 3-5 times of nature rubber.

2. Excellent oil resistance which is 4 times of NBR.

3. High mechanical strength. Its tensile intension and tear strength and burden capability are several times of common rubbers.

4. Excellent tolerance of acid, alkali, low temperance and organic solvent.

5. High metal-bonding performance.

6. Wide hardness range from Shore A10 to A100 adjustable.

Our Polyurethane Foam Filled Fender advantage

1. Our Polyurethane Foam Filled Fender are filled with high quality 100% closed-cell foam. This specific foam can provide high energy absorption with relatively low reaction force. Even the skin was punctured, it also is unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam filled fenders core cannot be ruptured when compressed.

2. Our Polyurethane Foam Filled Fender skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is unique elastomer specifically for fender applications. More thick filaments and elastomer are applied to both ends to better resist the defection and shearing force.

3. Comprising through central steel tube and external load distribution flanges at each end. Heavy duty internal chain connecting the end fitting through central tube is applied to transmit tensile load through the fender. All end fitting of Polyurethane Foam Filled Fender are hot-dip-galvanized.

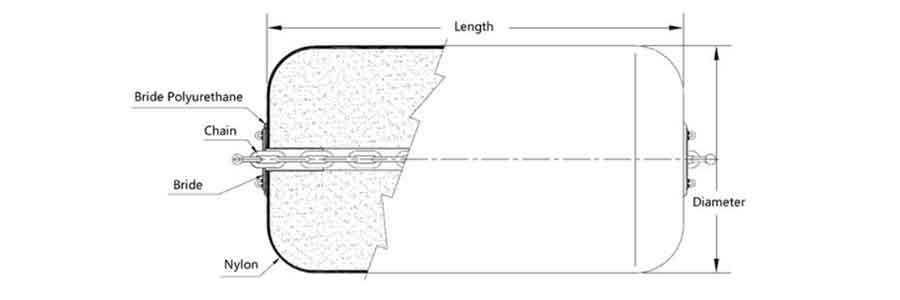

Drawing:

Size Chart:

| Specification | Compression deflation at 60% | ||

| Diameter | Length | Reaction force | Engergy absorption |

| mm | mm | KN | KN-m |

| 300 | 500 | 38 | 1.8 |

| 400 | 800 | 56 | 2.6 |

| 500 | 1000 | - | - |

| 1000 | 1500 | 205 | 49 |

| 1000 | 2000 | 274 | 64 |

| 1200 | 2000 | 337 | 93 |

| 1500 | 3000 | 624 | 216 |

| 2000 | 3500 | 990 | 456 |

| 2000 | 4000 | - | - |

| 2500 | 4000 | - | - |

| 3000 | 5000 | - | - |

| 3000 | 6000 | 2460 | 1695 |

| 4500 | 9000 | 19650 | 7860 |

Foam Filled Polyurethane Fender :

Marine Foam Filled Polyurethane Fender :

Foam Filled Polyurethane Fender is a compressive fender, uses polyurethane material as the outer protective layer, and PU foam material or plastic foam as buffer medium, and absorbs impact energy of ships by compressive strain during use, reducing destructive effect on docks and ships. It is mostly characterized by floating performance, and is not affected by tidal range; it has bright color and can be made into products with various colors according to customer demands.with counterforce from small to big, and high energy absorption, it is suitable for open sea open docks and gravity (dolphin) wharfs, especially docks with large tidal range and loading and lightering of two steamers in open sea.

Compared to other marine fenders system:

1. High wear resistance which is 3-5 times of nature rubber.

2. Excellent oil resistance which is 4 times of NBR.

3. High mechanical strength. Its tensile intension and tear strength and burden capability are several times of common rubbers.

4. Excellent tolerance of acid, alkali, low temperance and organic solvent.

5. High metal-bonding performance.

6. Wide hardness range from Shore A10 to A100 adjustable.

Our Polyurethane Foam Filled Fender advantage

1. Our Polyurethane Foam Filled Fender are filled with high quality 100% closed-cell foam. This specific foam can provide high energy absorption with relatively low reaction force. Even the skin was punctured, it also is unsinkable without absorbing water. With our unique laminating process, each foam core is integrity. The foam filled fenders core cannot be ruptured when compressed.

2. Our Polyurethane Foam Filled Fender skin is constructed of polyurethane elastomer which is reinforced with nylon filament. The polyurethane skin is unique elastomer specifically for fender applications. More thick filaments and elastomer are applied to both ends to better resist the defection and shearing force.

3. Comprising through central steel tube and external load distribution flanges at each end. Heavy duty internal chain connecting the end fitting through central tube is applied to transmit tensile load through the fender. All end fitting of Polyurethane Foam Filled Fender are hot-dip-galvanized.

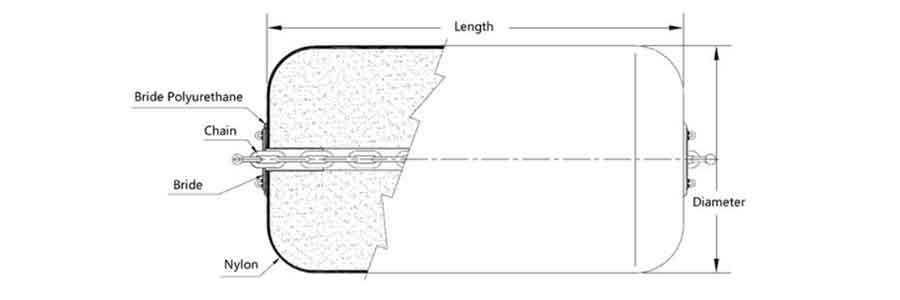

Drawing:

Size Chart:

| Specification | Compression deflation at 60% | ||

| Diameter | Length | Reaction force | Engergy absorption |

| mm | mm | KN | KN-m |

| 300 | 500 | 38 | 1.8 |

| 400 | 800 | 56 | 2.6 |

| 500 | 1000 | - | - |

| 1000 | 1500 | 205 | 49 |

| 1000 | 2000 | 274 | 64 |

| 1200 | 2000 | 337 | 93 |

| 1500 | 3000 | 624 | 216 |

| 2000 | 3500 | 990 | 456 |

| 2000 | 4000 | - | - |

| 2500 | 4000 | - | - |

| 3000 | 5000 | - | - |

| 3000 | 6000 | 2460 | 1695 |

| 4500 | 9000 | 19650 | 7860 |